Get in touch.

Dear,I will reply in 12 hours. All your message are protected!

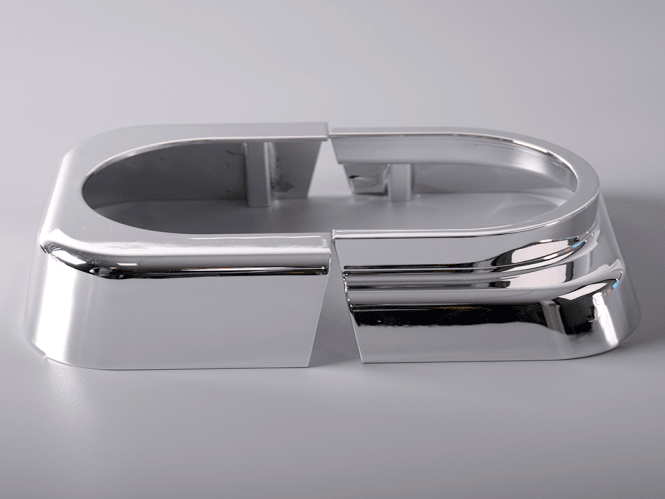

Rapid Prototyping Services, Professional manufacturer of CNC Prototyping and 3D Prototyping in China.

Washington: Researchers have successfully built and driven a drone using 3D printing technology.

Engineering students at the University of Virginia posted a video on YouTube showing that they designed and built a plastic turbine engine using 3D printing technology.

Executive at Maclean.

Headquartered at the defense contractor, saw the video and issued an announcement to the College of Engineering and Applied Sciences that they were looking for two summer interns to work on a new project involving 3D printing.

There's only one student, Steven Easter, and then the third one.

Major in mechanical engineering, responding to the recruitment announcement.

Easter's mission is to build an unmanned aerial vehicle in the summer using 3D printing technology.

In other words, plastic aircraft to be designed, manufactured, built and tested --flown.

Engineers use their consultants, Professor David Scheffler, an alumnus at the School of Engineering at the University of Virginia, and 20-

The veteran of the aerospace industry.

This is a difficult project.

Make a plane with 6. 5-

Foot wingspan, made of assembled 'printed' parts.

The students sometimes turn 80-

According to a university statement, working an hour a week, there are many long nights in the lab.

'This is a seat --of-the-

Pants at first. wham, bang.

But as we continue to design and print new parts, we constantly beat and become more confident, 'said Easter.

He said he had confidence in them.

'Eventually, in August and early September, aircraft and four test flights were assembled at Milton Airport near Keswick.

It reaches a cruising speed of 72.

4 kph, just the third 3-

printed aircraft known to have been built and flown.

In the first Test, when the aircraft glides around the site, the aircraft's nasal armour is damaged.

'We followed it, but we printed a new nose,' Easter said in a statement . '.

Sheffler said that the ability to make and modify new parts is a beauty of 3D printing, and he works with students from the School of Engineering's rapid prototyping lab.

Their task now is to build an improved aircraft.

Lighter, stronger, faster and easier to assemble.

This project is also their fourth. year thesis.

© 2005-2025 Shenzhen Tuowei Model Technologies Co., Ltd. | All Rights Reserved 粤ICP备11096697号