Rapid Prototyping Services, Professional manufacturer of CNC Prototyping and 3D Prototyping in China.

Rapid Prototyping Services, Professional manufacturer of CNC Prototyping and 3D Prototyping in China.

Shenzhen Tuowei Model Technologies accept small bulk of metal parts manufacturing. More than 45 sets automatic tool changing NC machine, with high-speed drilling center and +-0.01mm tolerance,all those elements determine high processing efficiency. Clients speaks highly of our fast delivery time. The processing products including watches, electronics, automobiles, toys, telecommunications, Office supplies and other miscellaneous industries, such as car parts, precision shaft.

So many foreign friends have chosen us!

Founded in 2002, with its own superb technology and efficient service, Tuowei prototype has expanded its market around Middle East, Europe, North America, South America, Southeast Asia and other areas.

Here is a picture of our customers who visited our company.

Item name | Silicon Rubber Prototyping Vacuum Casting Urethane Prototype |

Material | ABS, POM, PP, PC, PMMA,PE, PA(Nylon), PA+30%GF,PPS, PVC,PEI,PBT,PTFE, |

Surface treatment | Polish, sand blast, painting, dusting, ultraviolet, silk-screen, laser etching, electroplating, anodizing, passivated surface, black anodized, draw bench, water-transfer, CD grain lines, grain texturing etc. |

Lead time | 3-5days after confirmation |

File formats | Pro/Engineer, SolidWorks, Unigraphics, Auto CAD, (IGS, STP, STL and X-T) |

Service we provide | 1, CNC plastic prototypes/Metal prototypes 2, SLA/SLS plastic rapid prototypes 3, Vacuum casting (Silicone mould) 4, Automotive/Medical/Household prototypes 5, Design service (OEM service)

|

Terms of payment | T/T 50% Deposit in advance, balance before delivery |

The fields we can serve: 1. Electronic,digital camera,mp3/mp4,coffe oven,hair dryer,LED light case, television, calculators, GPS electronics, DVD/VCD player and etc 2.Medical devices,B Ultrasound scanner case, Ultrasonic diagnostic imaging care, and etc 3.Telecommunications: micro phone, speaker, monitor case, computer and etc. 4.Auto parts: dashboard, car lamp, bar, car door, motorcycle, scooter, bike and etc. 5.Household appliance: Cooker, air conditioner, TV, fan, shower, fridge, coffee machine and etc 6.Kitchenwares,crafts,perfume bottle,lighter,kitchenware,cookie molds,and etc. 7.Toys,game handle/controller,toy plane and etc.

|

|---|

Vacuum Casting Process

vacuum casting process is a process used to generate a tool to create short runs. Depending on geometry, master patterns can typically produce aproximately twenty five castings. Master patterns are usually stereolithography prototypes that have been sanded, primed, and painted to produce a Level 4 finish. In some cases, other physical prototypes can be used as patterns. The mold design is determined, and one half of the mold is mocked up using the master pattern and a two part liquid silicone rubber is poured over it, capturing all of the detail in the surface finish. After curing, the other half of the mold, complete with a fill for the urethane material and vents for air to escape, is prepared and then poured. When the second half of the mold is ready, the master pattern is removed and the mold is ready for use. Molds are retained at ProtoCAM for a year before being disposed of.

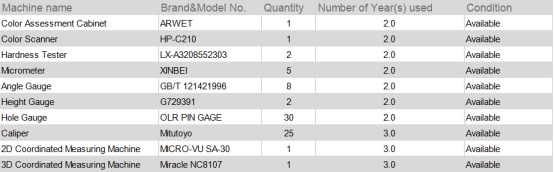

All of the parts must be checked according to the 3d and 2d files by our QC department before shipment.

We will issue Material Data Sheets(MLDS),COC and testing reports together with the shipping parts.

Certifications

We have ISO 9001:2008 certification for our plastic and metal prototypes service.

To protect your 3d files and other informations,we have taken two methods.

1.We could sign NDA with you as you required.

2.All of the computers in our company have installed confidential software.Without the password,no one could get access to the files.

We could accept FEDEX,DHL,UPS,EMS,Aramex as shipping options.It will take about 2-3 working days to deliver.

Besides,we could also provide a cheaper way by logistics express.It will take about 4-7 working days to arrive in foreign countries.

We will provide you with several options so that you could choose the best one you prefer.

Tuoweis your full-service partner of small and large products,with strong engineering support,

superior customer service and state-of-the-art processing control techniques.

Just send us 3D files in .IGS/.X-T/.PRT/.STP/.STL format, also please advise Quantity / Material / Colour / Surface Finish ,waiting for you at any time.

Tuowei,Make Models Your Way!

© 2005-2025 Shenzhen Tuowei Model Technologies Co., Ltd. | All Rights Reserved 粤ICP备11096697号